the

forestay

Rationale:

(Al's

note: This was written in 1981 and still has validity but on SHADES, we

now have a further modification of this system that will be explained

under

"Forestay Tackle" below.)

The forestay serves no structural function once your jib is up and

properly

tensioned. At that point it becomes slack and does nothing but

interfere

with your jib tickers (wind indicators). What you could use, however,

is

a straight-line reference from bow plate to the hounds (where forestay

is attached) in order to check how far the luff of your jib is sagging

off to leeward while you are close-hauled. To accomplish this, we

replace

the bottom 18" of stay by a shock cord loop rigged in such a way as to

take up slack as the jib luff is tensioned. This keeps the forestay

wire

under some tension (and fairly straight) and out of your jib at all

times.

As a back-up to the shock cord we use a short length of thin line (3

mil.)

which we tie between the end of the wire and the shackle (or cotter

pin)

at deck level.

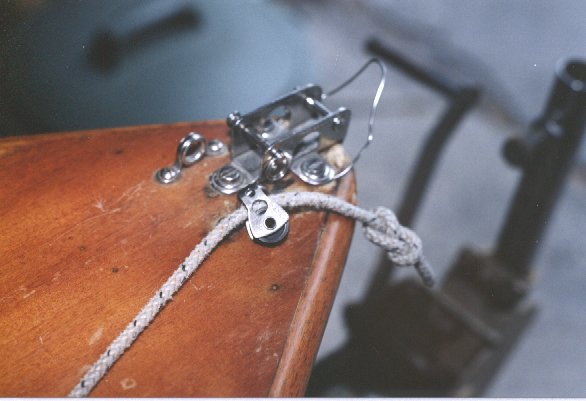

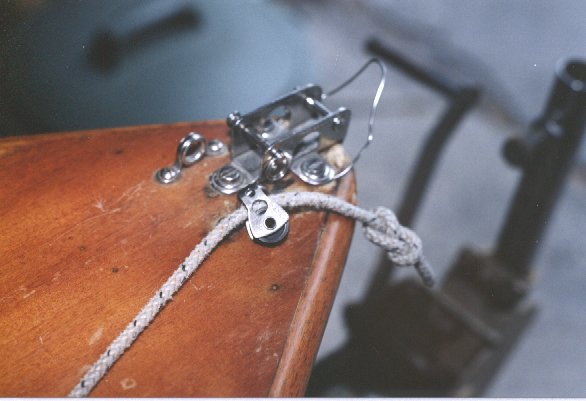

Extraneous

note: The photo below shows one other

item that sort of has to do with the forestay - installation of a

spinnaker

sheet catcher to help prevent the sheet from going under the boat. Ours

is simply thin stainless steel wire the ends of which are wrapped

around

the two front screws under our forestay plate. You'll note that it gets

a lot of abuse:

.....

.....

.....

Installation:

The shortening of the wire part of your stay must be done with good

wire

cutters and a swaging tool. Before doing this, you take three feet of

¼"

shock cord, and make a loop out of it by overlapping the two ends about

1" and putting a seizing around the overlap with whipping line. Then

hoist

your jib to maximum tension (for a blow), attach the loop via shackle

or

cotter pin at the bow while detaching the forestay there. Keeping the

seized

part of loop away from bends, stretch the loop parallel to the jib luff

until the cord begins to stretch. At the same time pull the stay tight

parallel to jib luff. Mark (with tape) the point on the stay that is

reached

by the top of the loop. Cut the wire there and swage in a loop with

thimble.

Use a small shackle to connect wire loop to shock cord. Tie one end of

the back-up line (with a bowline) around cotter pin or through shackle

at deck and the other with a round turn and several half hitches

through

wire loop.

Note:

I discovered that forestay wire is very stiff and hard to swage and

have

replaced my forestay with wire cannibalized from an old main halyard

which

is much easier to work with!

.....

.....

.....the

forestay tackle

Rationale:

The jib halyard/magic box combination is easily used to put up to 400+

lbs. of tension on the rig. Such pressure translates into mast

compression

which in turn becomes pre-bend when you push forward on the mast about

1 to 2 metres above deck level.

The

problem

with using the jib halyard to get the required tension is that pre-bend

is only needed in light airs when such tension removes all jib luff sag

for which all jibs must be designed. This in turn makes for an

overly

flat luff entry which makes the steering groove unacceptably narrow and

steering consistently within the groove impossible.

What we

therefore do is crank up the tension with the halyard and then take up

any slack in the forestay with the aforementioned tackle. Once the stay

tackle is well tightened and cleated, it keeps the rig tension required

for pre-bend while the halyard can be slackened off to give us any

amount

of luff sag that feels comfortable.

On SHADES, we have

cut enough

off the bottom of our forestay to accommodate a 30-40 cm. tackle which

consists of

-

about 1.5 metres

of 4 mm. pre-stretch

line

-

this is tied to

the becket of

an RWO #R4959 (V-jamming block with becket intended for windsurfing

use)

attached to the bow plate where the forestay used to be attached

-

from the becket,

the line goes

up about 30 cm. to an RWO micro-block (#R1530) which has been swaged

into

the new loop at the lower end of the forestay

-

the line then

leads down around

the sheave of the R4959 before exiting through the V-jammer which we

have

facing aft

The amount of pre-bend

you get depends on

-

how far aft your

spreaders are

angled

-

the amount of rig

tension applied

-

the inherent

flexibility of your

mast section

NOTE:

Abbott masts are harder to pre-bend but word from the Fanshawe Fleet is

that using a minimum diameter (¼”) mast pivot pin facilitates

such

bend.

|