|

RIG

IT RIGHT - the JIB HALYARD

Halyard wire recommendations:

- main halyard: about 22' of 3/32"

7 x 19 stainless steel wire (more

than 22' if your halyard exits at the foot of the mast!)

- jib halyard: about 21' of 1/8"

7 x 19 stainless steel wire (more

than

21' if your halyard exits at the foot of the mast!)

Rationale:

This halyard should be 1/8" wire since

it must take a much greater strain than the main halyard. It will be an

equal partner with the sidestays (which you will note are also 1/8"

wire!).

I am assuming here, that you are replacing an old jib halyard, and that

you already have a tensioning device installed.

Installation:

1. Swage a loop lined

with

a thimble into one end of your new halyard wire. The length of this

wire

will need to be around 20', depending on the luff wire length of your

jib

and how you will get to your tensioning device. On SHADES, our

halyard

comes straight down to the magic box which is about a foot below the

gooseneck.

If you lead your halyard out the bottom of the mast at centreboard

level

and then come up or aft to your tensioning device, you will, of course,

need more wire.

2. Take the mast down,

and

thread the un-swaged end of the wire through the jib halyard entry

block.

On the old-style Proctor masts, this wire then needs to be encouraged

to

slide down the mainsail groove towards the gooseneck. On Abbott masts

or

the newer Proctors, where the halyards are internal and exit at the

foot

of the mast, the blocks at the foot will have to be moved to thread the

wire through.

3. Get your jib out

but do

not attach its tack to the stemhead fitting. With the mast still down,

shackle the thimbled loop of the halyard to the head of the jib, making

sure that the other end of the halyard is prevented from going back

into

the mast (get a friend to hold it or tape it securely to the mast).

With

the loose halyard end still secured (!), put the mast back into its

upright

position. Now attach the tack to its proper spot. Take the loose

halyard

end and pull the halyard as tight as you can reasonably get it

by

hand. Mark the spot where the wire goes around the hook of your

tensioning

device. (I do this by slightly

kinking the wire in that spot.)

4. Undo the tack of

the jib

so that you can pull more halyard out of the mast. This makes the

cutting

and swaging a lot easier. Cut off enough excess wire to leave about 3 -

6"

of wire after the 'kink' or other such mark. Now swage a 3 - 6" loop

into the

'loose' end of the halyard.

5. If you use #4

Dacron braid

line (cheap!!!) as a halyard tail, you can simply tie this onto the

loop with a bowline. #4 line runs nicely, even up the mainsail groove,

and if its thinness makes you nervous, soak the part where rope meets

wire

with 5-minute epoxy glue to keep the #4 line from fraying too easily.

You'll

need less than 20' of this line. My apologies for not knowing more

precise

dimensions!

6. Now you can haul

the jib

down and stow your jib halyard as usual.

the bottom of the loop

should

be about a foot below the bottom black band (i.e. gooseneck in normal

position).

Mark the position of the bottom of the loop on the mast.

If

you already have the right halyard but wish to add a tensioning

device...

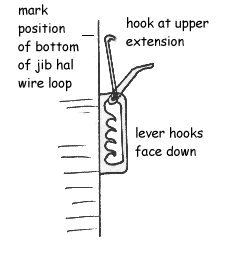

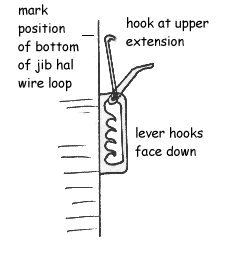

| Your

Highfield Lever (Holt-Allen

42601) or Magic Box (Harken 116) must be attached such that its hook in

its uppermost extended position (see diagram on right) matches the

position

of the halyard's bottom loop when the jib is hoisted. There are

numerous

possibilities for attachment. To attach the tensioning device directly

to the extension of a sail groove, the best set-up I've seen is the use

of bolts with square nuts that have the corners turned inwards. This

lets

them really grip the inside of the groove ans prevents the lever or

magic

box from sliding along the groove under the considerable pressure that

will be exerted.

If you are

going through the

main body of the mast, beware of screws' points getting caught on line

that run up and down the innards of the mast. You need to file the

self-tapping

screws accordingly or do as I do and use Monel rivets.

|

|

|

There is a

picture of the Harken #116 Magic Box on line

but they've blocked it from being copied - dumb, but there you have it!

|

Length

Adjustment: As many of us have already

found

out the hard way, a wire halyard that is the absolutely perfect length

for our current jib may suddenly be an inch or two too short or too

long

for the next jib. To avoid the need for new halyards or a new placement

for the magic box or lever, we have added a shroud plate (see

illustrations

below) to the sail end of the halyard. The shackle goes into the

single

hole at the left end (below, left) while the swaged eye of the

halyard

slides in from the right end as many holes as is necessary. With our

current

jib, that is 6 holes in, which allowed the chain plate's sides to gape

a bit and left me with the fear that the spi halyard might get caught

in

there. To avoid such a possibility, and to make sure we don't lose the

horseshoe-shaped part of the shackle when the pin is out, we have taped

up the entire sides (but not, of course, the ends!) of the shroud plate

(which I believe is Ronstan #RF2331, or so it says in my local

catalogue...)

as you can see in the photo of our mast stored for trailering, on the

right

below:

..

|