|

... Aboard SHADES,

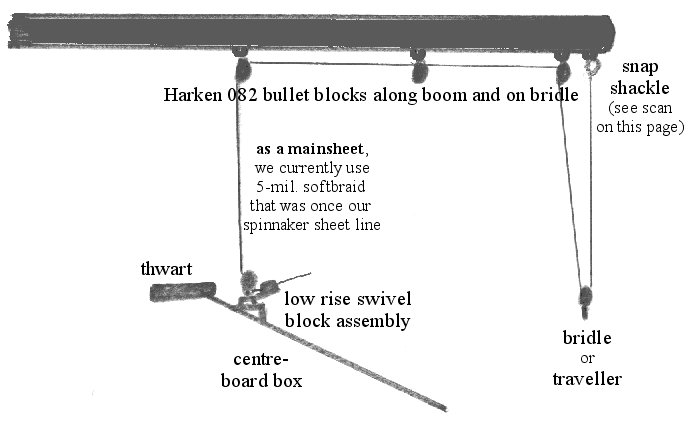

we have used a number of different mainsheeting systems, and I must say

that I think the current system that we've been using for the past

three

years (see photo below) seems to be pretty well flawless for

our

needs.  You may be able to see that we used to use a(n adjustable) bridle with 36' of 5-mil softbraid for a mainsheet. This "new" mainsheet was once part of a very old spi sheet that was pressed into service at this year's Nationals. When our 8-mil braided rope being just a bit too short finally annoyed me enough, I took it out of the swivel cleat for a run and then rushed to re-thread it for a rapidly approaching beat. It was a close race with only half a beat to the finish, and a bad time to discover that I had (inadvertently!) installed a new barber hauler for the starboard jib sheet! Well, I was

not going

to repeat that manoeuvre! So - during our on-the-water lunch, I

rummaged about in the aft tank (which still had not quite returned to

normal

after Mike Mac had totally emptied it just to sail one club race at

TS&CC!)

and found our old 58-foot continuous spi sheet from before the days of

the "balls system". It was in there to comply with the 25' towing line

requirement plus it could be pressed into service if our somewhat

frayed

spi sheets gave up the ghost. And now it developed a third function: it

was threaded in as a new mainsheet, tested for length with the bridle

pulled

as flat as it goes and the vang off. Then I left an extra two feet of

rope

just in case I had overlooked some possibility - and ended up with a

mainsheet

that is 36 feet long.

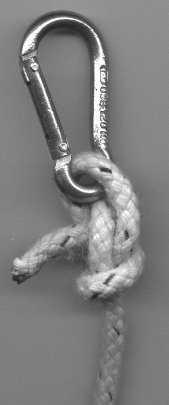

The Swivel Block & Cleat Assembly As luck would have it, I inherited what I believe to be the perfect swivel block assembly (see photo below). Made by Barton Marine and given the number 42600, it has a short, low-rise plate that attaches the metal cam cleat to its base. Much as I love Harken stuff of almost every description, I have dumped at least twice when using a borrowed boat that had their standard high-rise swivel cleat. The problem was that, during a tack, the sheet cleated itself on the Harken swivel whereas my Barton swivel takes a conscious effort to cleat - i.e. I have to reach down, or push on the sheet with one foot, to make it cleat. I find this easier to do than to explain, and for me, it is certainly much safer (and drier!) To find it on line go to Barton Marine > Products > Dinghy & dayboat fittings. .....  I believe the glass boats tend to come with a spot provided for the swivel mount at the aft end of the centreboard box. If I had a glass boat, I would not use this location since it's too low for my taste. And above all, it's too far aft - considering that I go aft of the mainsheet each time I tack, and that the further aft I go, the more transom drag I get. I have just jotted this down off the top of my head more or less. Your critique, questions and/or suggestions for improvement will be welcome c/o Uncle Al. |